Loading Guide - Unitising Loads

Loading Guide - Unitising Loads

National

Heavy

Vehicle

Regulator

This guide is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered by this guide can be found on page 35 of the Load Restraint Guide 2025.

What is unitising a load and why is it beneficial?

Unitising a load means to group or bundle smaller items into a single, larger pack. This creates a more secure, stable and consolidated load that can be easily restrained. Unitising streamlines handling, reduces the likelihood of movement during transit, protects the product and minimises the potential risk of items toppling and becoming dislodged.

By grouping products together, loading and unloading is quicker as the number of individual items that need to be handled is reduced. Unitising helps with load placement / construction and weight distribution, which can improve vehicle stability and reduce risk of damage to both the load and vehicle. Transporting goods that have been unitised are safer for drivers, other road users, and those who load or unload vehicles.

Commonly used methods

Different methods of unitising can be used depending on the products being transported, some methods are more effective than others. For example:

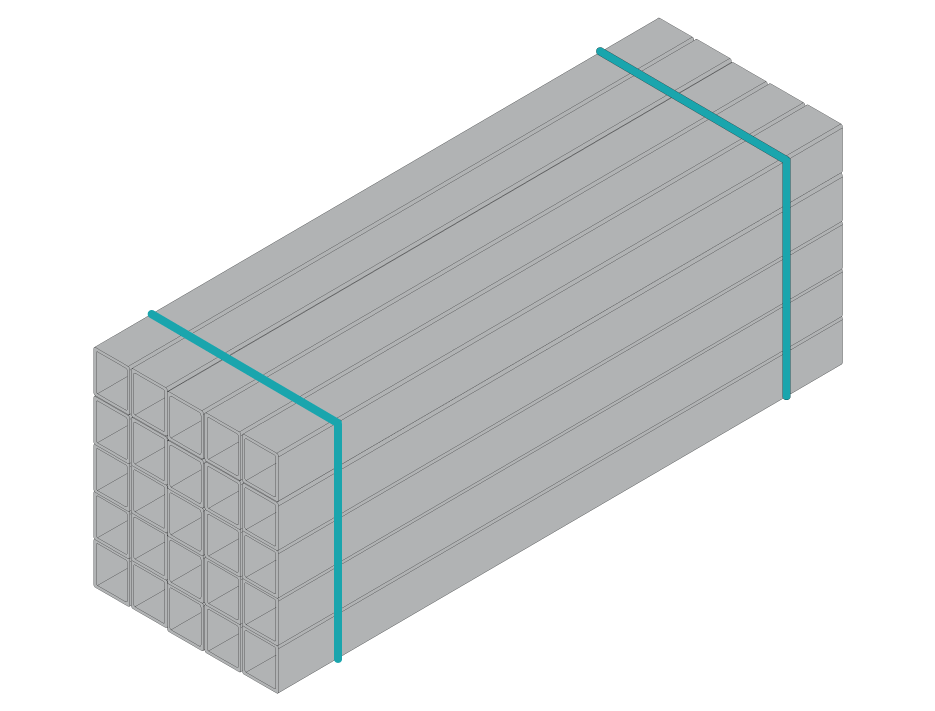

Banding

Usually made of steel or plastic, tightly bound around a load often tensioned using pneumatic or electric tools or machinery to keep items together. This is particularly effective for securing bulky, heavier loads, such as metal pipes, timber or large machinery components that require extra reinforcement.

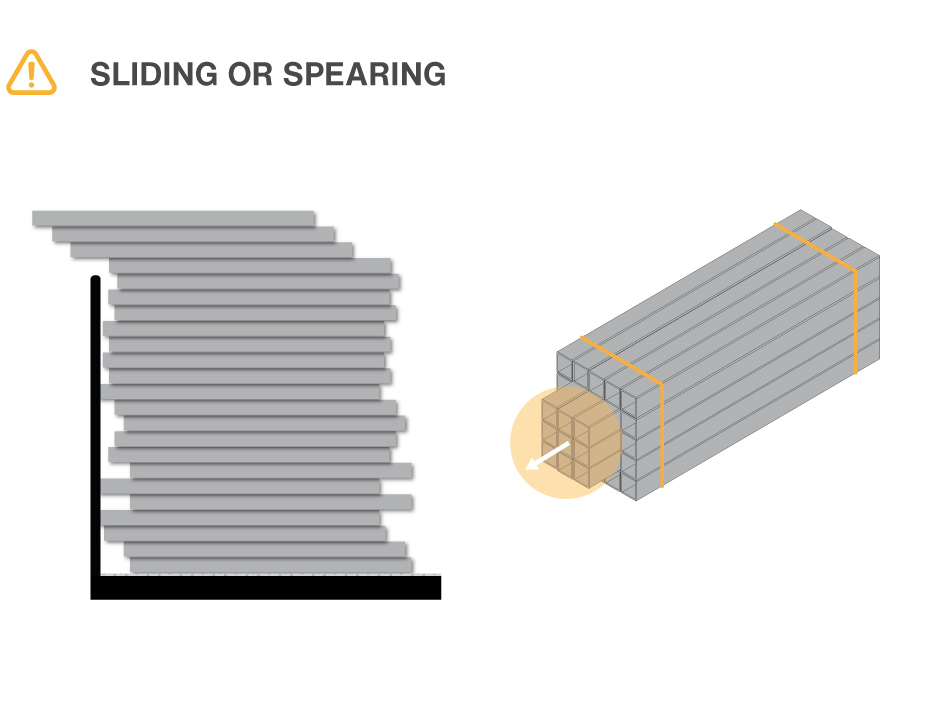

Note: Do not rely on unitising alone to restrain all items in a pack during transport, it may not be enough for low friction items, which can still shift or spear.

Strapping

Similar to banding and used when additional support is needed, such as securing items on pallets. Strapping uses materials such as polyester, nylon, webbing or steel straps to hold items together.

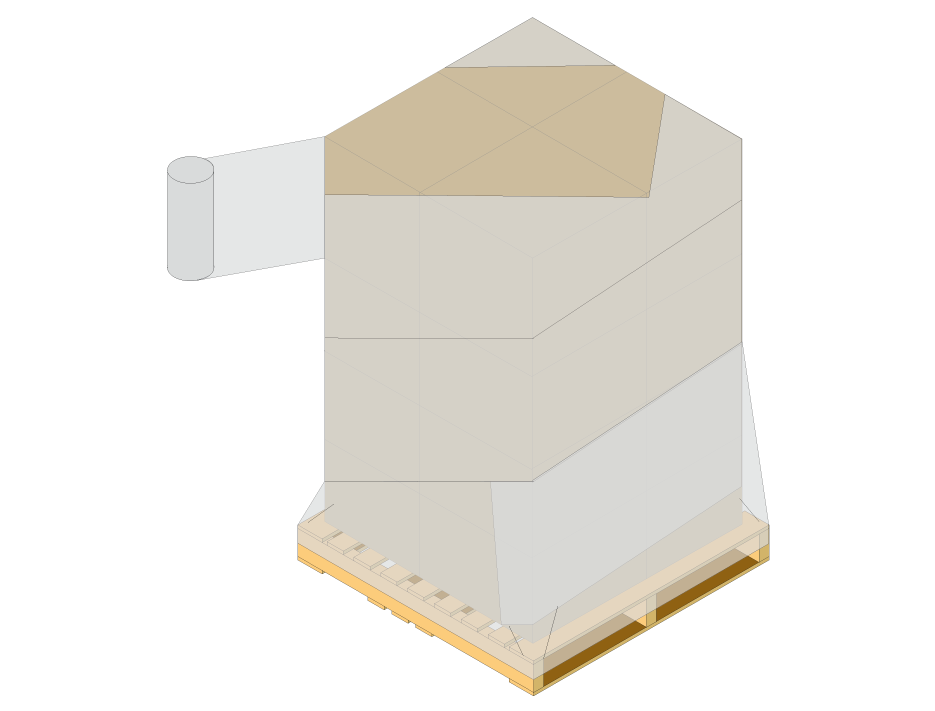

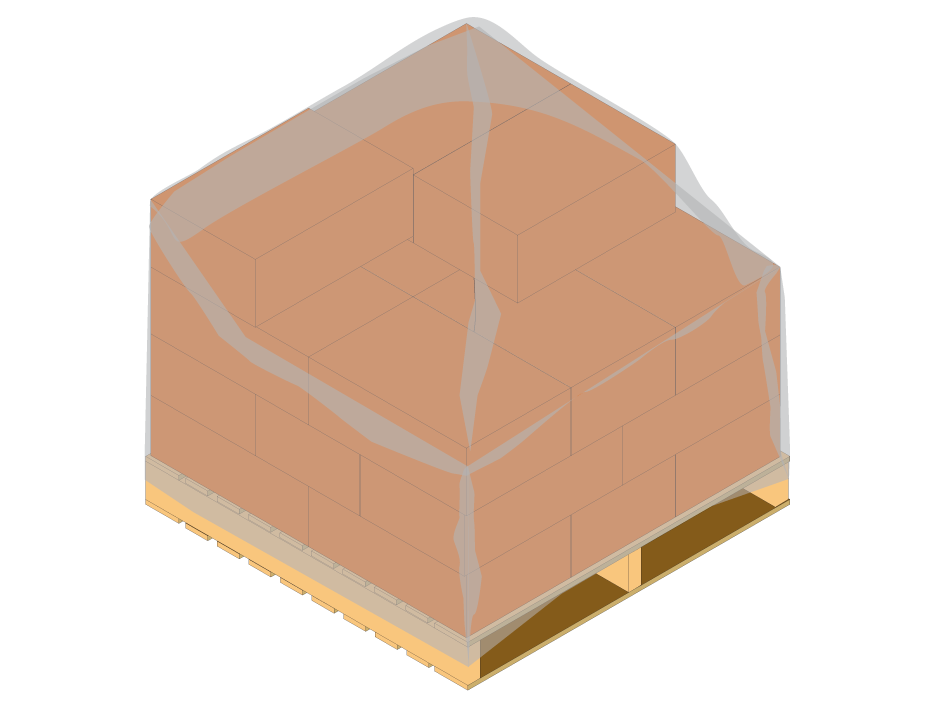

Stretch or shrink wrapping

Stretch wrapping uses a stretchable plastic film to tightly wrap around a load to hold it together. Shrink wrapping tightens when a heat source is applied to increase the tension around a load.

Gluing

Used in combination with other methods like stretch or shrink wrapping. Gluing helps to bond items together, which is useful for loads that require more consistent contact during transport. This could include products packed in cardboard cartons and ceramic or stone slabs. Using glue stops them from sliding or dislodging from the pack.

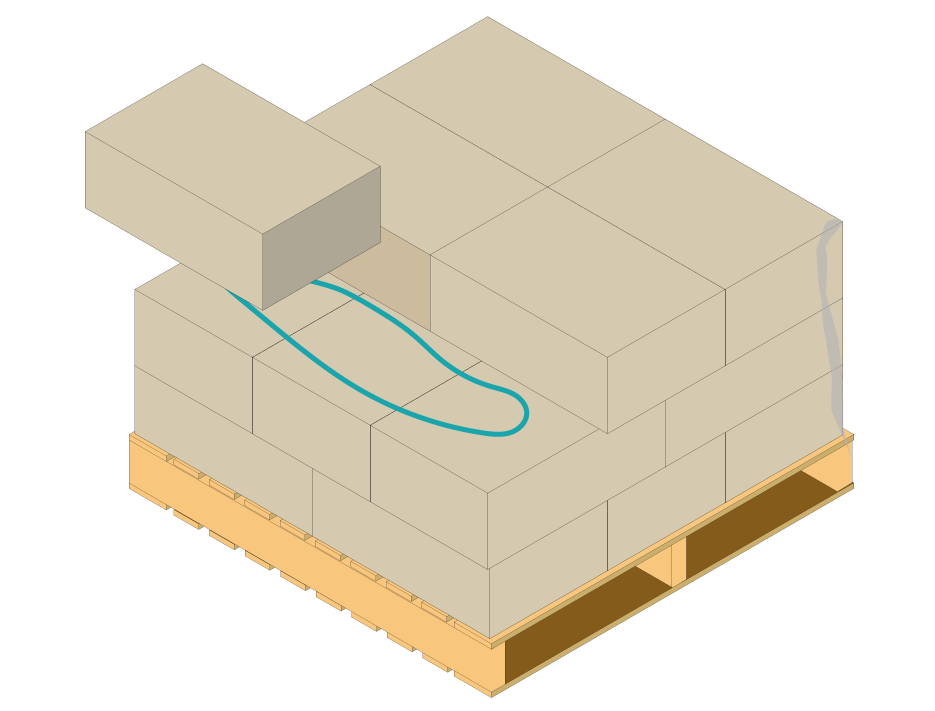

Scalloped/specialist timber framing and lashings

This method incorporates custom timber frames, used with lashings to stabilise and protect loads with irregular shapes or components such as large pipes and mining drill bits.

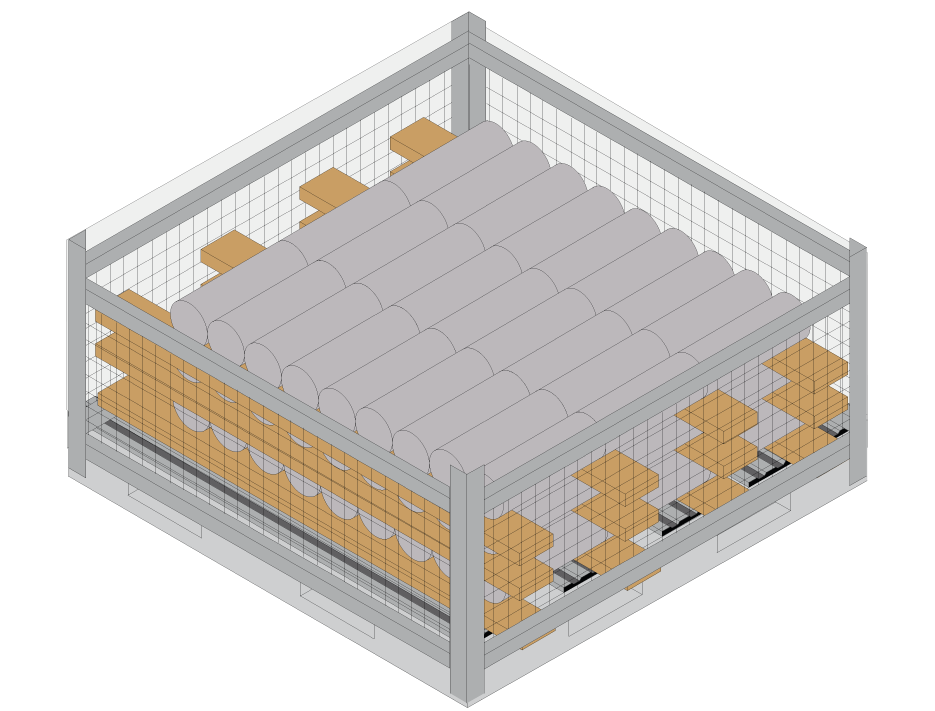

Stillages

These are sturdy, often custom-built containers used to securely hold and transport items. Stillages are particularly effective for stabilising and protecting loads with irregular shapes or heavy weights, like machinery parts, construction materials or bulk items.

How do I choose the best unitising method for my load?

When unitising a load, the pack must be secure on its own to prevent dislodging during loading, unloading and transit. The load restraint method selected to secure the pack to the vehicle must work alongside the chosen unitising method. For example, a loaded pallet shrink-wrapped to keep individual bricks in place is secured on the vehicle with lashings that won’t cause the shrink wrap to tear or fail during transit.

The best unitising method depends on the load type and the type of vehicle that is being used. To choose the right method, start by considering the load’s characteristics. For example:

- For easily crushed items (e.g. lightweight cardboard boxes, thin plastics or fragile glassware), steel banding is not ideal as it could damage the product.

- For heavier or bulkier items (e.g. metal pipes or drilling equipment), stronger methods like custom timber framing with lashings or stillages provide the needed support and stability.

By selecting the right unitising method based on the load’s characteristics and the type of vehicle used, load stability and safety can be improved and the risk of damage reduced.

Can unitising be used as a form of load restraint on its own?

No, unitising alone is not sufficient for load restraint. It can form part of a complete load restraint system. To secure a load effectively, combine unitising with other methods such as blocking, containing and tie-down.

Tips

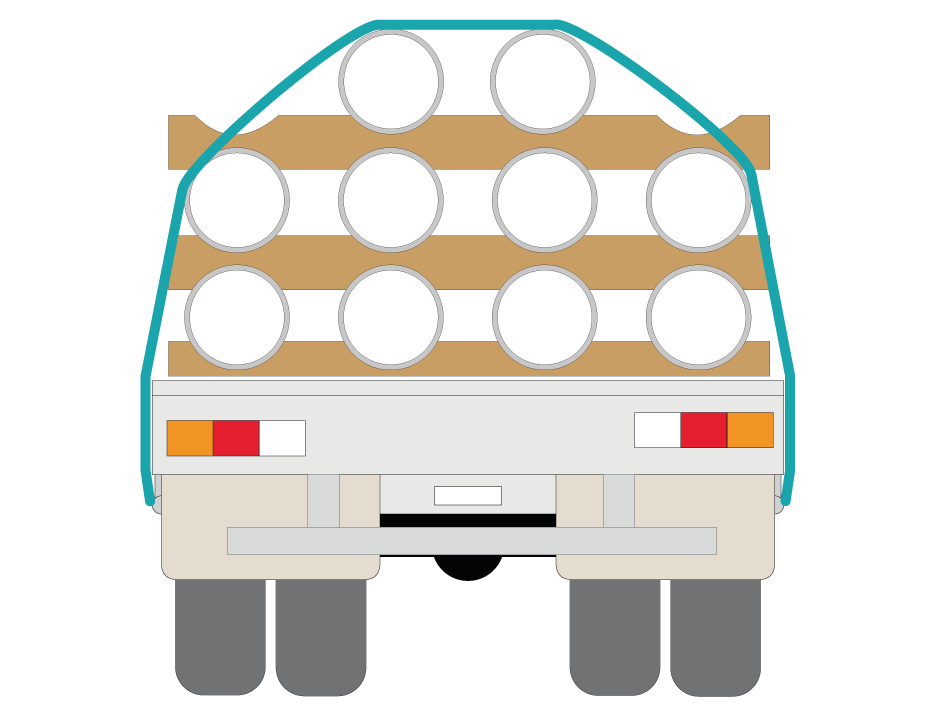

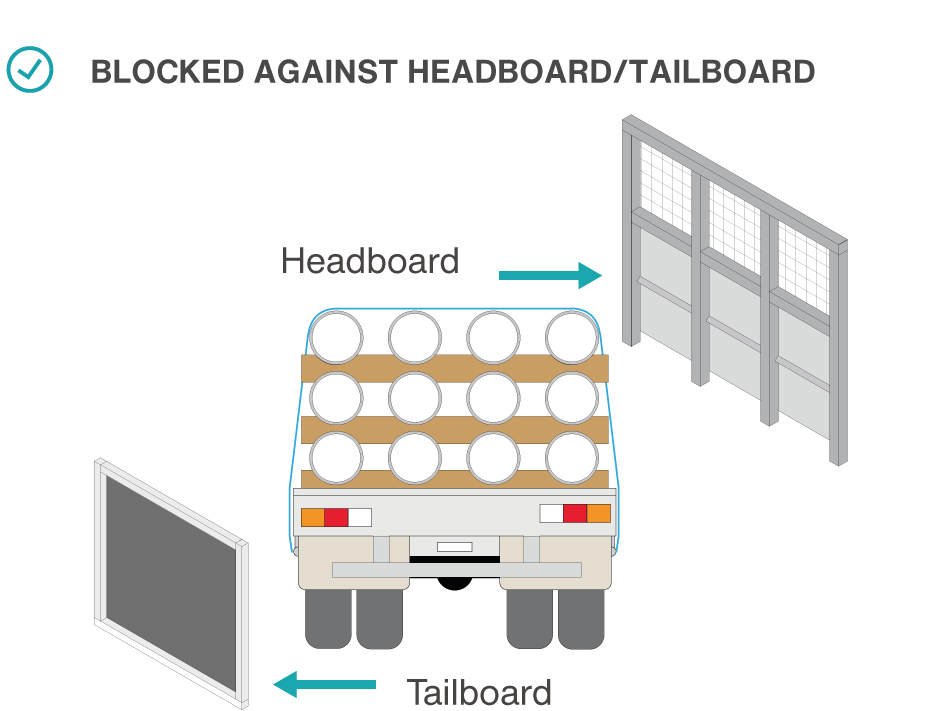

Use rated headboards for low friction products that may spear, like pipes, beams or metal sheets where clamping may not be enough to prevent parts of the load moving. Always make sure the load is below the height of the headboard, unless an additional method or structure is being used to prevent parts of the load spearing or moving during transport and heavy breaking. Blocking is the preferred method for keeping a load secured.

Risks

Good practice

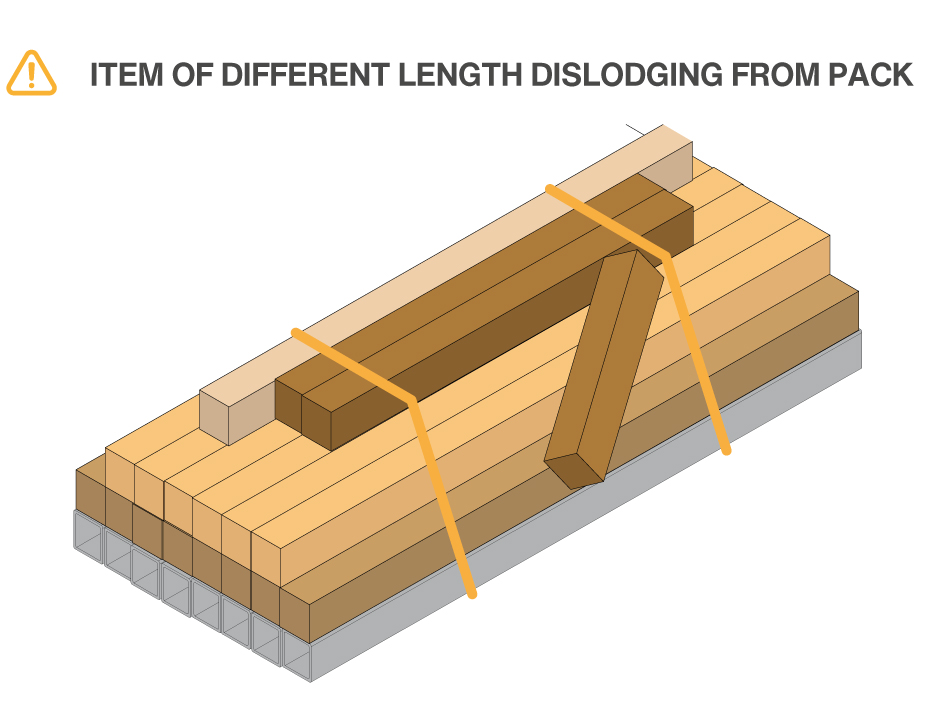

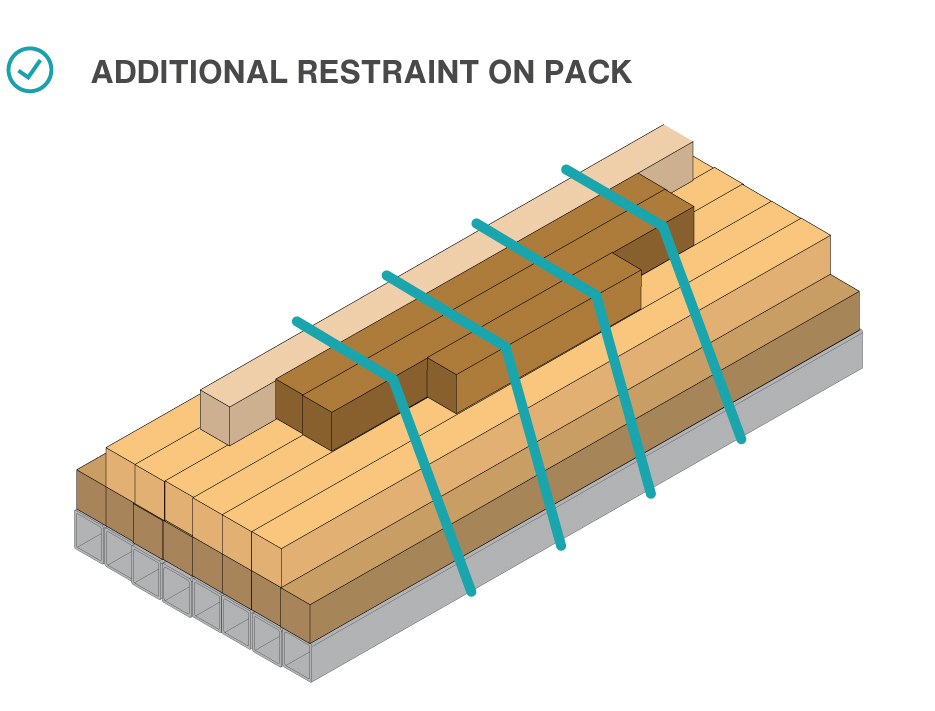

Use a method that keeps the entire pack together, and use additional strapping or wrapping where necessary, especially for items like processed timber of different lengths.

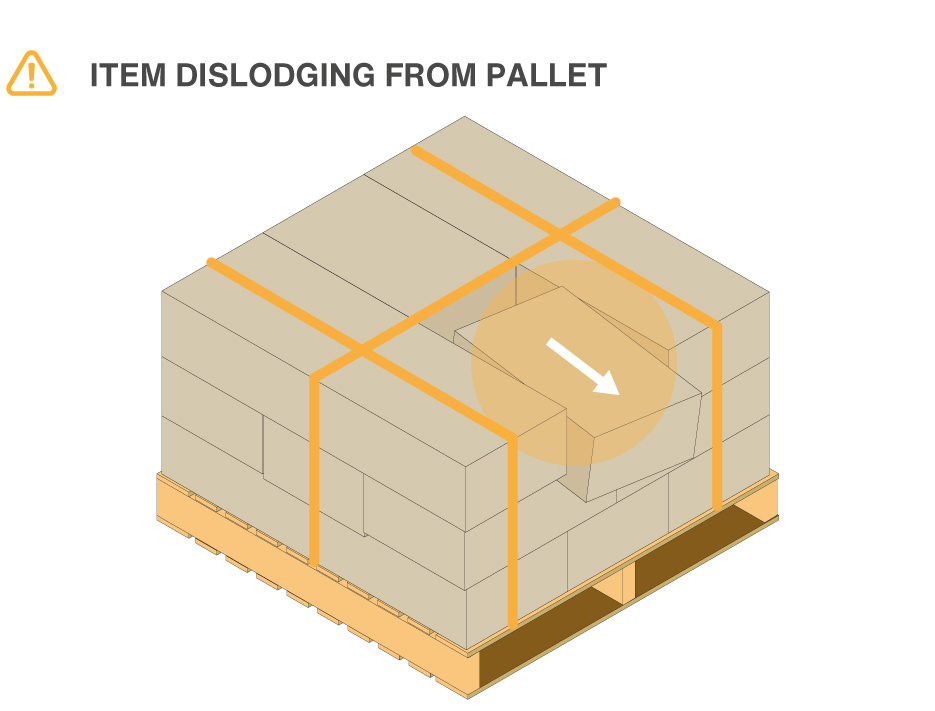

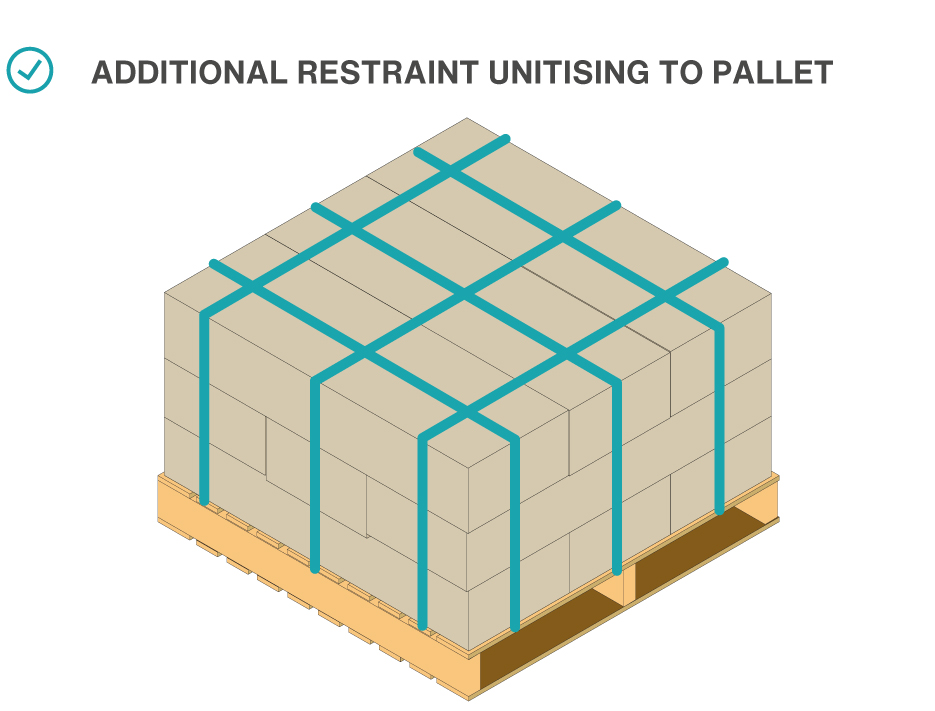

Risks

Good practice

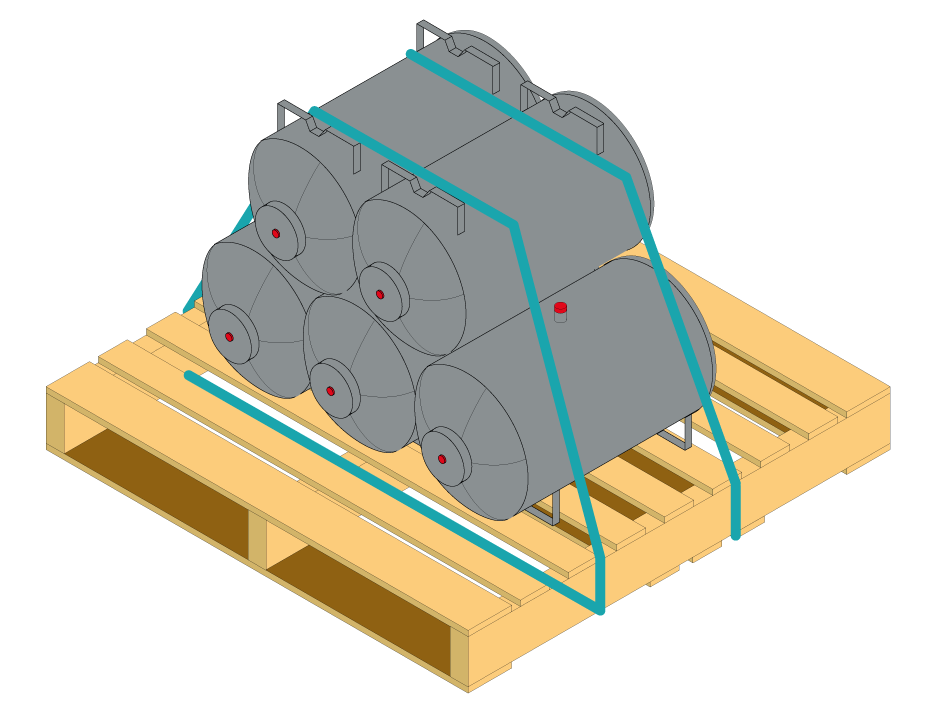

Ensure that there are no loose items within the unitised pack. Loose items are at risk of becoming dislodged during transit. For example, make sure bags of cement, drums or boxes are all securely packed and stable.

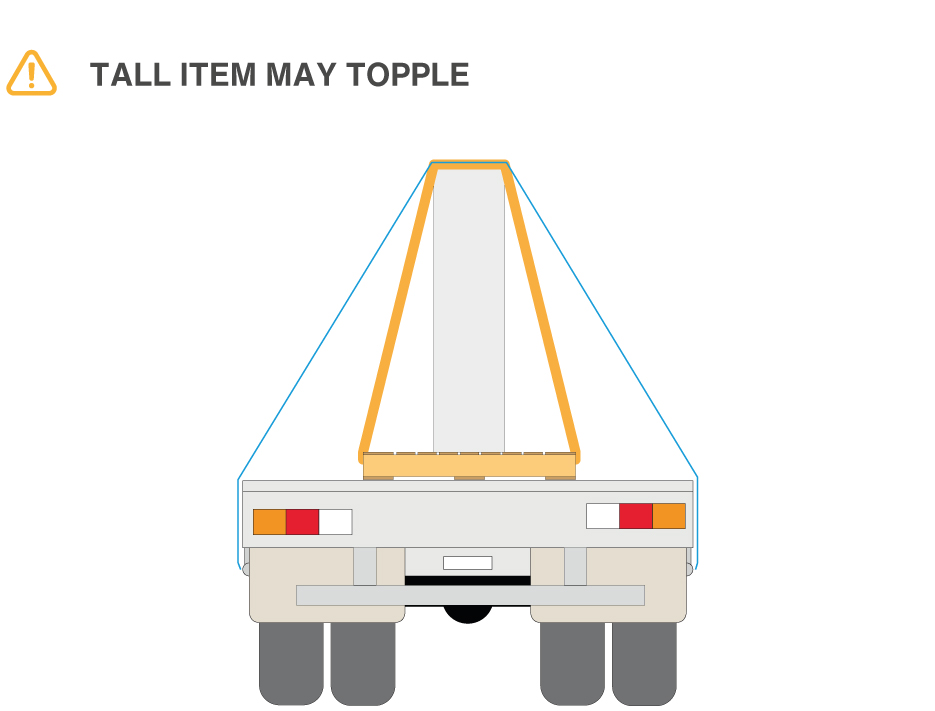

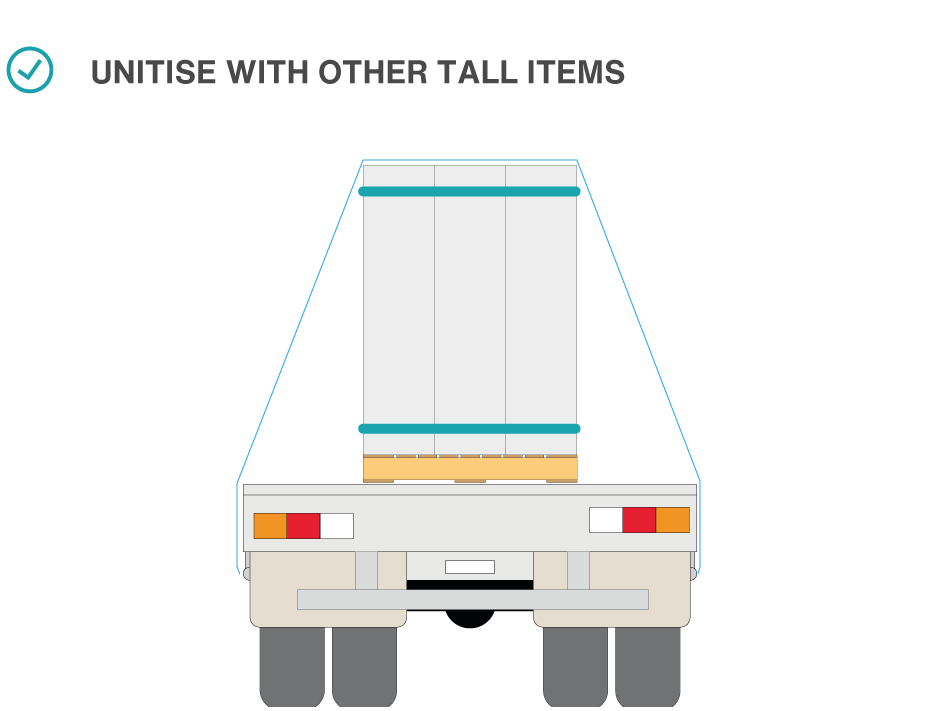

Risks

Good practice

Support tall items by unitising them together, this way it can help avoid toppling when turning corners or during heavy breaking. Blocking tall items against a headboard is also recommended.

Risks

Good practice

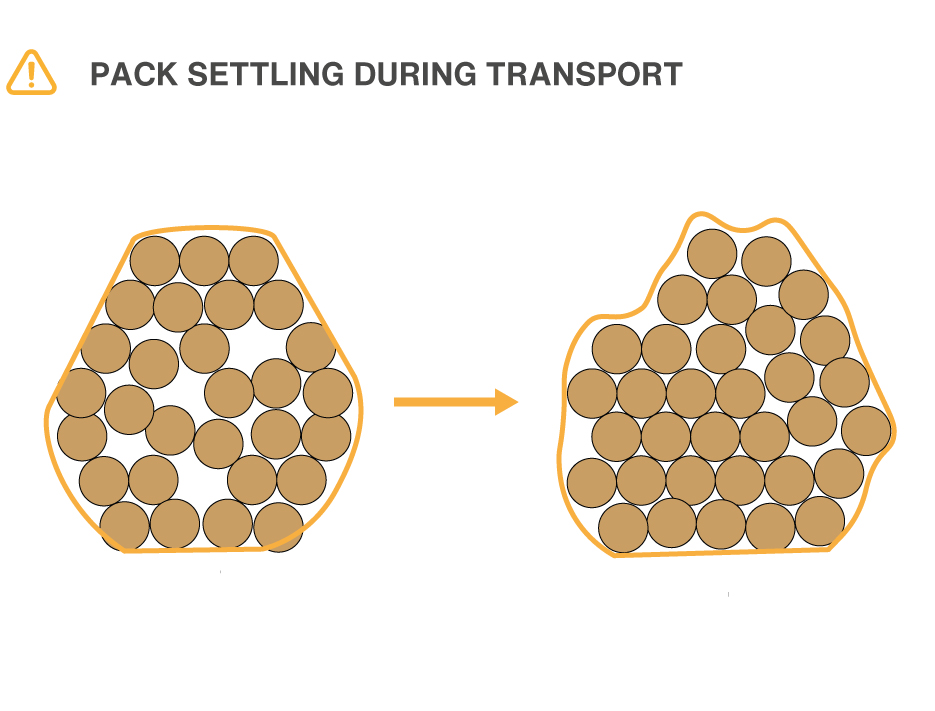

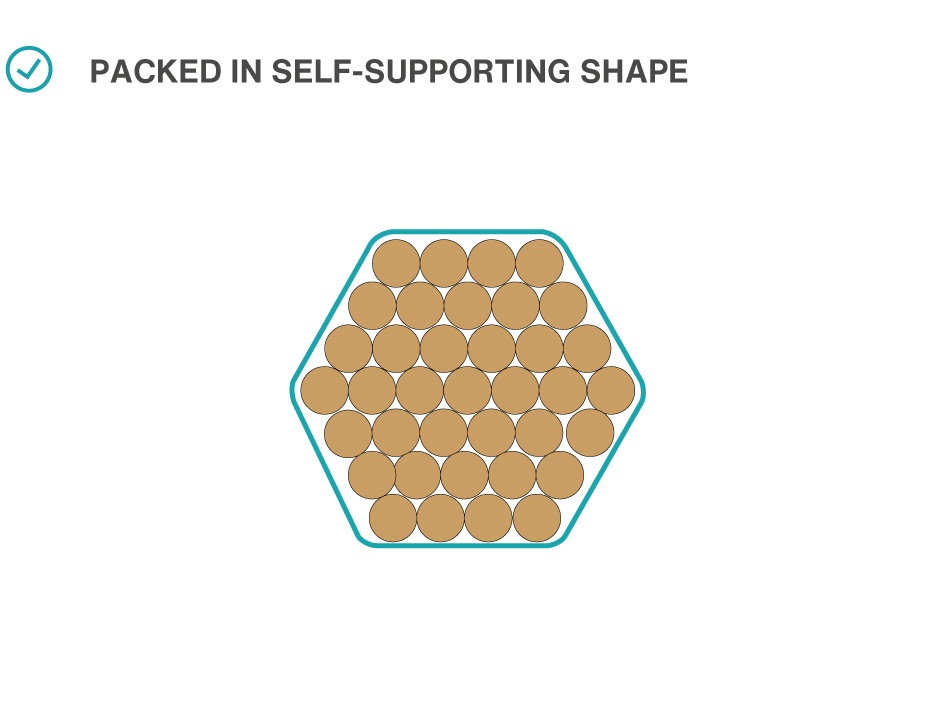

Avoid gaps within the unitised load. They can change shape during transit as items could come loose from the pack.

Risks

Good practice

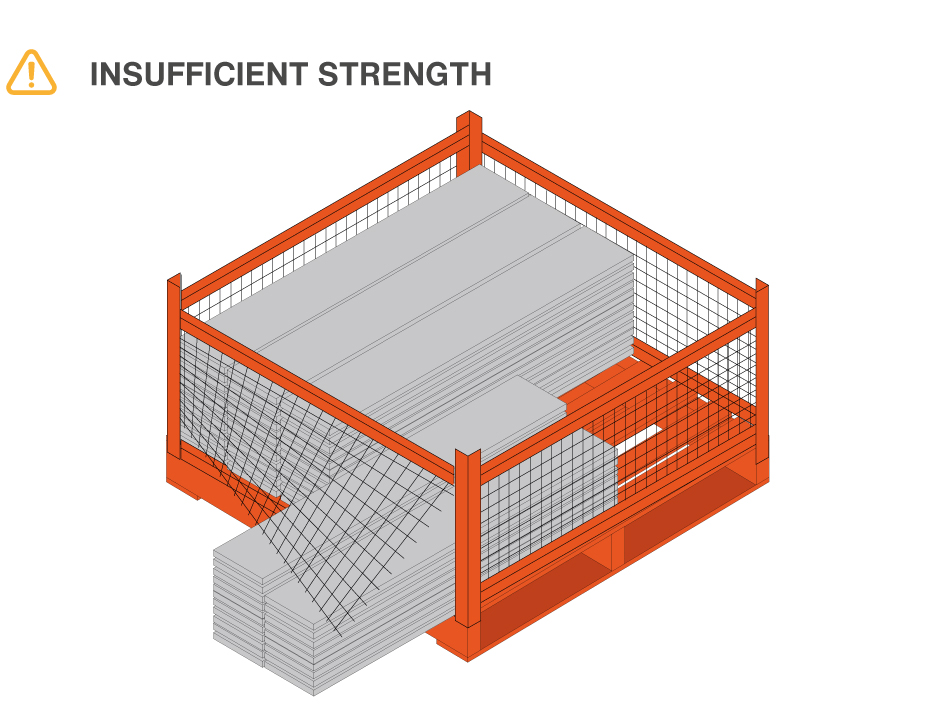

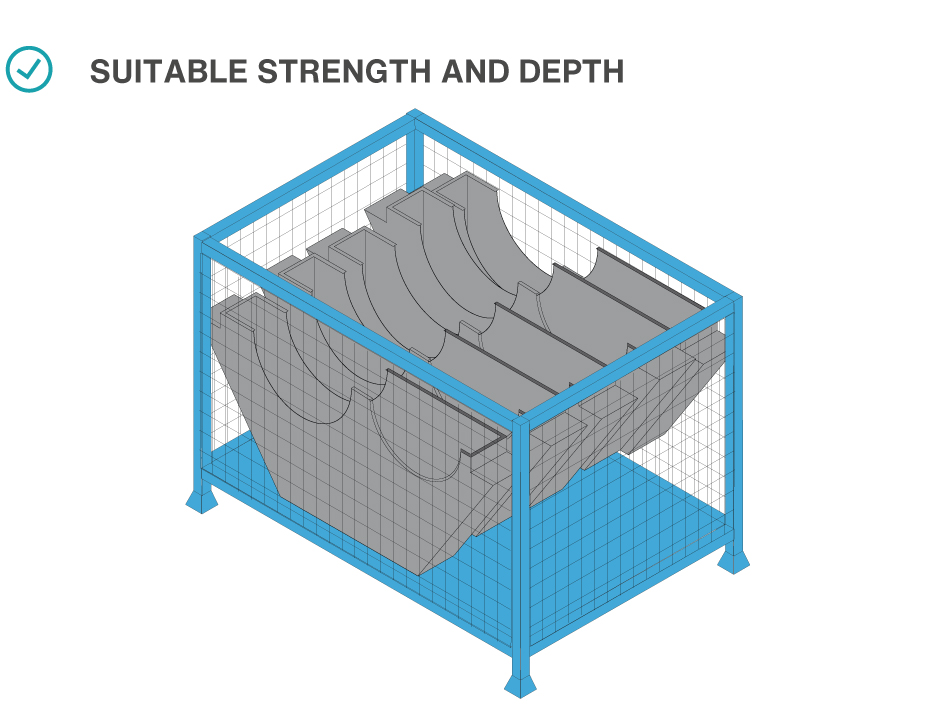

Stillages can be a useful option to simplify restraint requirements for loads that have lots of loose pieces. Stillages should be strong enough to restrain all items and should be deep enough, so they don’t bounce out.

Risks

Good practice

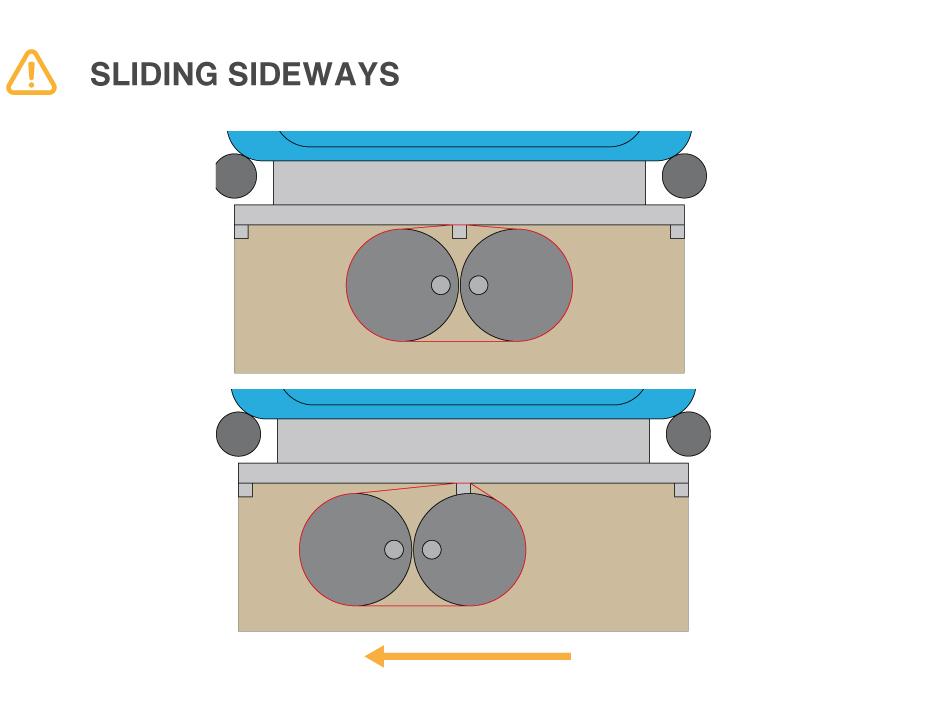

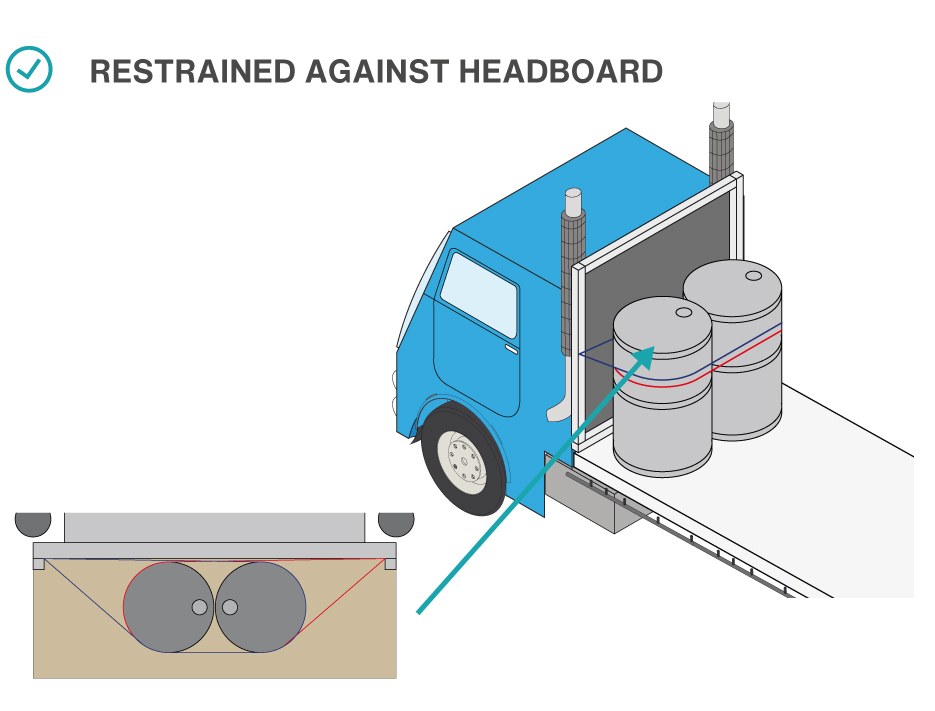

When unitising loads in drums, avoid tying drums horizontally to centre posts as they can move sideways and become dislodged. Instead, secure them against a headboard or use other items in the load for support.

Risks

Good practice

Case study

A heavy vehicle was loaded with several pallets of cardboard rolls. The rolls were stacked on the pallets and wrapped with stretch wrap, but they weren’t properly secured to prevent movement.

The load was placed too far away from the vehicle’s headboard, leaving a gap of more than 200mm. When the driver stopped suddenly, the rolls dislodged from the pallet.

Not only was there not enough stretch wrap placed around the rolls of cardboard and pallet, but the unitised load was not secured on the vehicle. Due to the weight and height of the load, the rolls came loose and could have fallen from the vehicle, creating a risk of injury to other road users.

This incident shows the importance of not relying solely on the unitisation method for securing heavy or tall items on pallets. Proper unitising means making sure that each roll is firmly secured to the pallet, with additional load restraint to prevent movement of the unit during transit.

Accessibility tools

Accessibility tools