Loading Guide - Key elements of a load restraint system

Loading Guide - Key elements of a load restraint system

National

Heavy

Vehicle

Regulator

This guide is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered by this guide can be found in the Load Restraint Guide 2025.

What is a load restraint system?

A load restraint system is the term used to describe the method or approach for securing a load on a heavy vehicle. An effective load restraint system will prevent the load from becoming dislodged or moving excessively during transport. It may include a combination of load restraint methods and equipment to keep you and others safe. For example, friction matting to enhance grip, pallets for organisation and stability, shrink wrapping to tightly bundle items together, edge protectors for cushioning and support, and straps or chains to secure everything in place. Together these make up the load restraint system.

Why are load restraint systems important?

Any load on a vehicle must be properly restrained to ensure safety and comply with the Heavy Vehicle National Law (HVNL). A load restraint system should be strong enough to withstand the forces the vehicle experiences during transport, including emergency braking and minor collisions. A well-designed load restraint system is essential for:

- Safety - Keeps the load stable and secure, preventing it from dislodging or falling off the vehicle, which could result in serious injury or death to the driver or other road users.

- Compliance - Complies with the HVNL loading requirements.

- Asset Protection - Reduces the risk of damage to road infrastructure, the load and the vehicle.

- Efficiency - Streamlines the loading process, saving time and resources.

Designing a load restraint system

There is no one-size-fits-all approach to load restraint. The appropriate restraint system will depend on both the nature of the goods being transported and the type of vehicle being used. For large, unusual items it is best to seek professional assistance, as the restraint requirements can be quite complex. For more common types of freight, the Load Restraint Guide provides helpful information that will assist in choosing the safest restraint system.

A well-designed load restraint system will keep the load stable and secure for the entire journey. The development of a loading plan is one way to ensure that you have a robust load restraint system that’s suitable for the load and the vehicle used to transport the load. Loading plans guide the load restraint process to ensure its applied consistently. More information on this topic can be found in Loading Guide - Loading Plans.

Key elements of a load restraint system

Using an appropriate load restraint system is key to ensuring the safe transport of freight.

The below steps are vital when developing a load restraint system. Following these steps will help to keep drivers, loaders and other road users safe, prevent loading and unloading incidents, load loss, and ensure compliance with HVNL loading requirements.

Safety

Before loading or unloading a heavy vehicle, the priority must always be to make sure safe work practices are established and followed at every step of the process. Always use appropriate loading equipment and methods and make sure everyone understands their role.

For example, ensure:

- procedures are documented and loading plans are used

- drivers and loaders are trained on proper procedures and loading practices

- exclusion zones have been established

- the load’s stability has been checked before beginning to unload

- if the driver is present, there is clear communication between the loader and the driver

- if persons enter the exclusion zone, stop work

- regular reviews of procedures are conducted, and thorough records are kept.

1. Load assessment

Begin by understanding the load characteristics, including:

- Mass - Know how much the load weighs.

- Dimensions - Know the size of the load, including length, width and height.

- Centre of gravity - Identify the point where the load is balanced.

- How fragile it is - Assess if the load can easily be damaged.

- Friction - Evaluate how much the load will resist sliding or shifting.

- Packaging - Check how the load is packed / unitised, if it’s likely to fail during the journey and how the packaging will affect how the load needs to be restrained.

Understanding these details will help in choosing the right restraint system to transport the load safely.

Tip: If the load mass is uncertain, under-load or use scales to measure it accurately. You can also confirm the mass using documentation or manufacturers specifications.

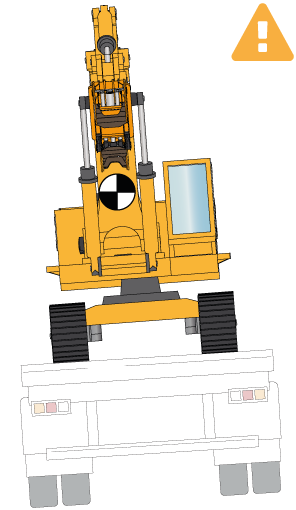

2. Vehicle selection

- Choose a vehicle with enough capacity and dimension for the load.

- Ensure that the load won’t overhang or be too high when placed onto the vehicle.

Tip: The vehicle chosen should provide good roll stability, especially for loads with a higher centre of gravity. It must also have the necessary securing points and equipment to keep the load in place and should contain and minimise movement for liquids or loose materials.

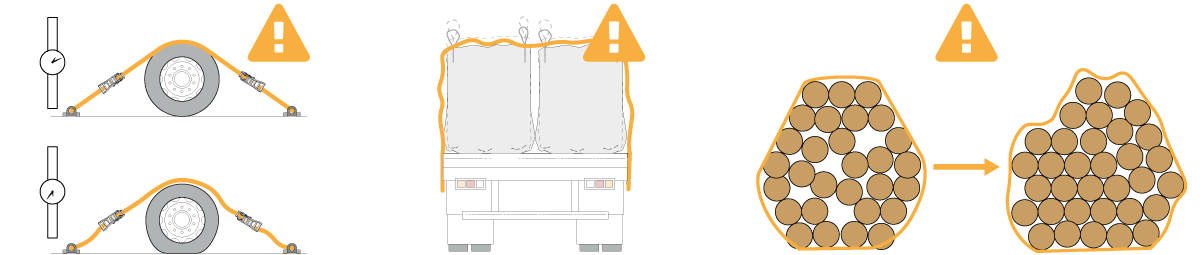

3. Restraint equipment and vehicle inspection

- Before use, check the vehicle structures and restraint equipment are in good working condition and strong enough to restrain the load.

- Use rated restraint equipment that is serviceable and regularly inspected.

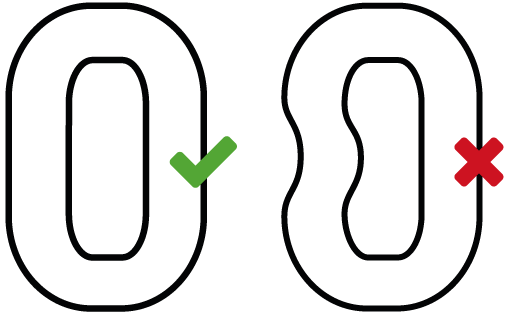

Inspect load restraint equipment for damage or excessive wear, and check lashings are strong enough to restrain the load.

Tip: Even minor wear and damage can reduce the restraint equipment’s capacity to restrain the load effectively, putting you and others at risk.

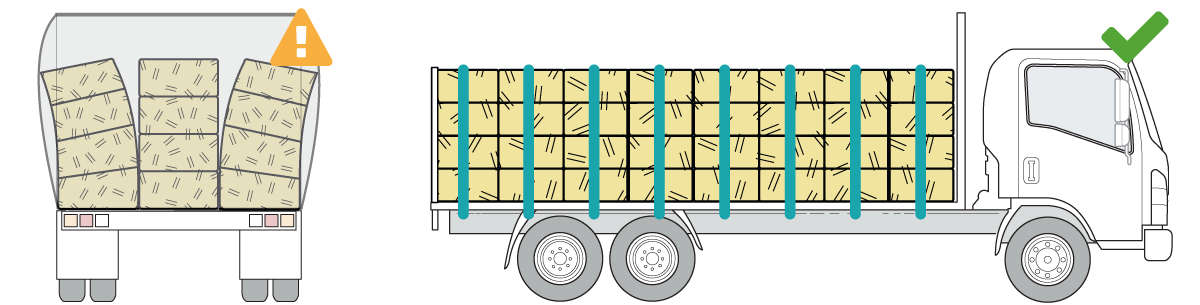

4. Restraint methods

Select a suitable restraint method based on the load and vehicle type.

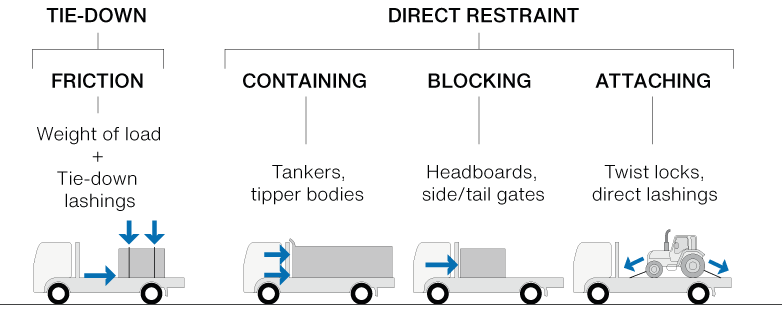

There are two basic methods that can be used to restrain the load, either tie-down or direct restraint. A combination of these restraint methods can be used and may be necessary to meet the loading requirements.

If you are unsure, have the load restraint system assessed and certified by a qualified engineer.

5. Load positioning

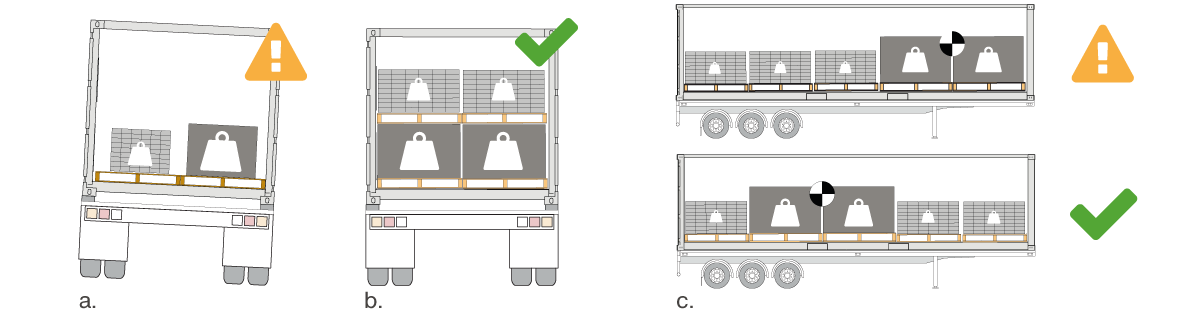

Correct load positioning is important for keeping you and other road users safe. Ensure that:

- the load is placed with the centre of gravity near the vehicle’s centreline

- heavy objects are loaded first

- weight is spread evenly across the deck and axles to maintain vehicle stability, steering, and braking.

Tip: Avoid projections, as they can pose a danger to others and cause damage. Position dangerous projections facing away from the driver and ensure they do not protrude outside of the vehicle and comply with dimension requirements.

6. Load stability

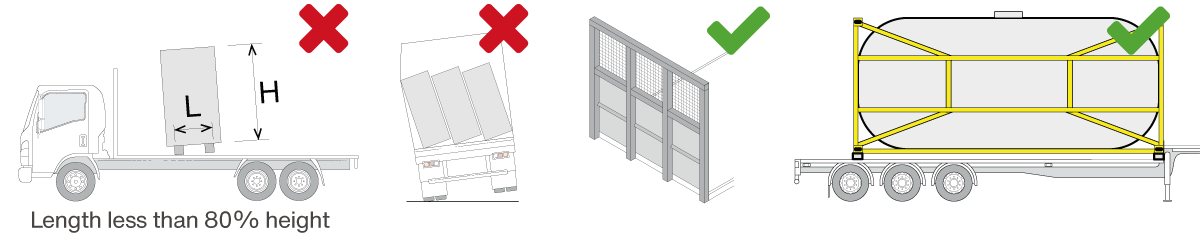

Make sure the load remains stable throughout the journey. Increase the stability of high loads by:

- placing against a rigid structure - headboard or drop deck trailer

- increasing footprint - strapping multiple items together

- fully tensioning lashings

- using direct lashings with limited amount of stretch.

Tip: To reduce the risk of rollover, be cautious when turning or braking when transporting loads that have a high centre of gravity or are prone to topple.

7. Securing

Use enough restraints to secure the load and prevent movement during normal operating conditions. Ensure the restraints are capable of withstanding the forces the vehicle may experience during transport, including emergency braking and minor collisions. This is especially important for tie-down systems that rely on friction.

Tip: If in doubt about whether the load has enough restraint, add more restraints to ensure it stays in place. It is better to have too much than not enough.

8. Driving adjustments

When driving a loaded vehicle, think about how the load type and position affect stability, steering and braking.

Loads with a high centre of gravity are less stable. Unevenly positioned loads reduce stability further. “Live” loads, such as liquids, loose materials or animals, can be prone to rollovers and uneven weight distribution can cause wheels to lock up during braking.

To prevent rollovers, avoid sudden vehicle movements that shift weight or affect vehicle stability and drive at a suitable speed for the conditions. Be mindful of your vehicle’s dimensions and mass. This is especially important around corners, roundabouts, under bridges and near obstructions.

9. Check the load

Periodically check the load and restraints during your journey to ensure the restraint system remains effective and the load is secure. Some loads can settle and shift, causing lashings to loosen. The frequency of checks depends on the load type. It also depends on the restraint system, road conditions and how well the load is packed.

Tip: Certain loads, such as bales and sacks, may need more regular checks and re-tensioning.

Remember - Every load is unique, check your restraint system.

Accessibility tools

Accessibility tools