Loading Guide – Toppling Risks

Loading Guide – Toppling Risks

National

Heavy

Vehicle

Regulator

This guide is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered by this guide can be found in the Load Restraint Guide 2025.

Understanding toppling

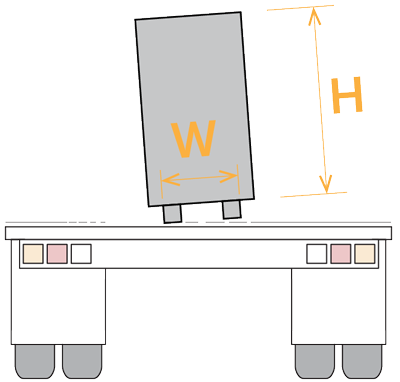

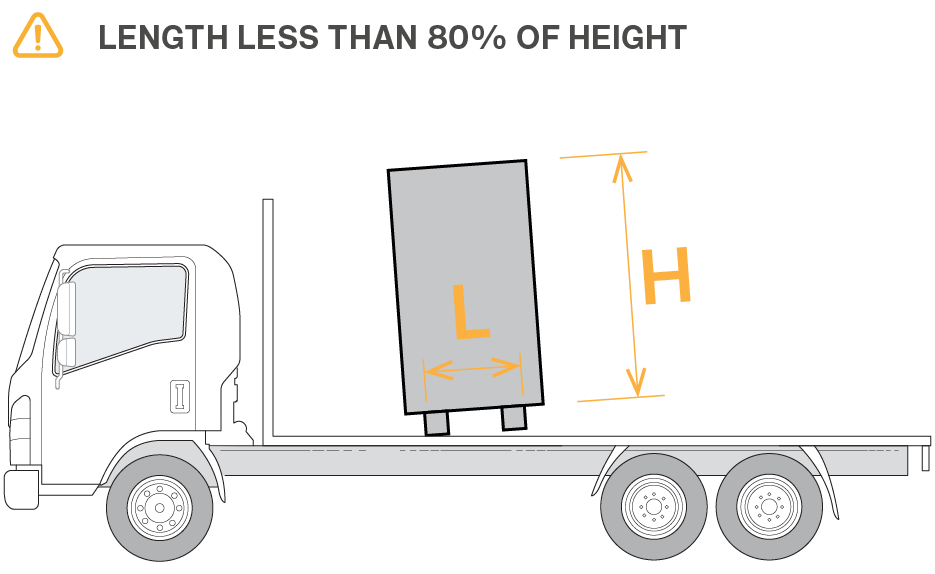

Toppling is something that can occur when a load becomes unstable because it is too tall compared to how wide or long it is. Tall, narrow and short loads are particularly at risk of toppling because their height results in a high centre of gravity, making them less stable. Even with careful securing, sharp turns, sudden stops or uneven road surfaces can trigger toppling of the load. Understanding the risks and taking steps to address them is important for safe transport.

Key risk factors for load toppling

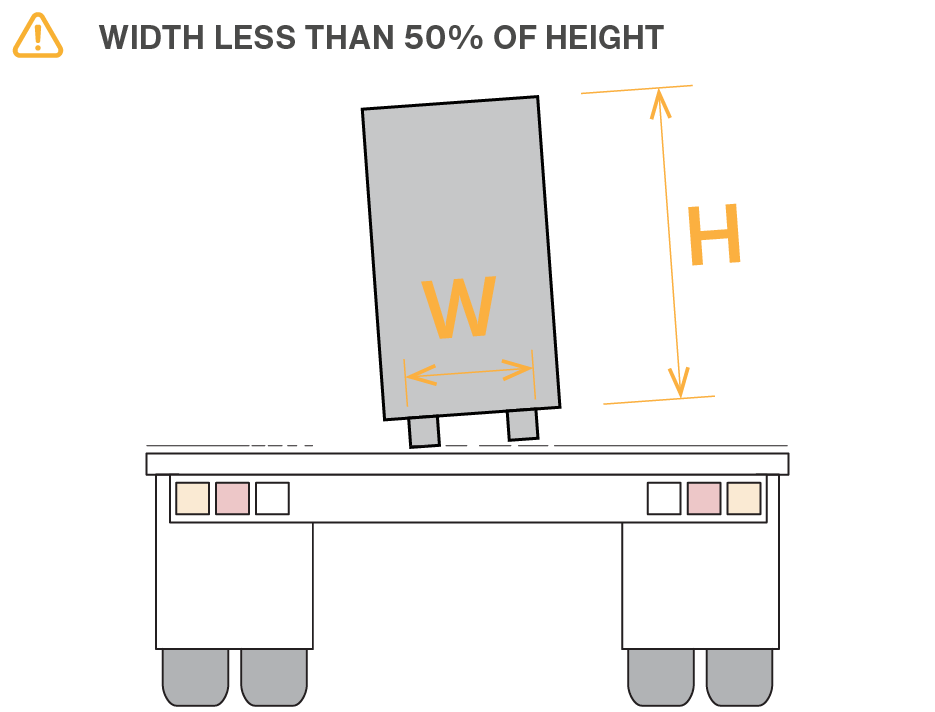

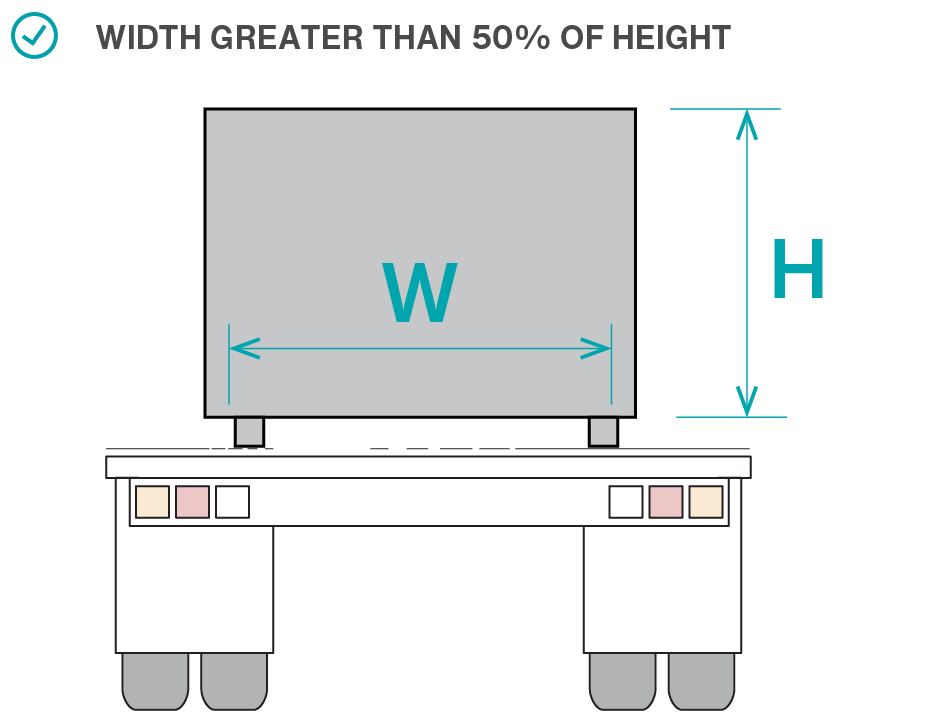

- Height to width ratio - If the load’s height is significantly greater than its width, it is more likely to tip over as it is less stable.

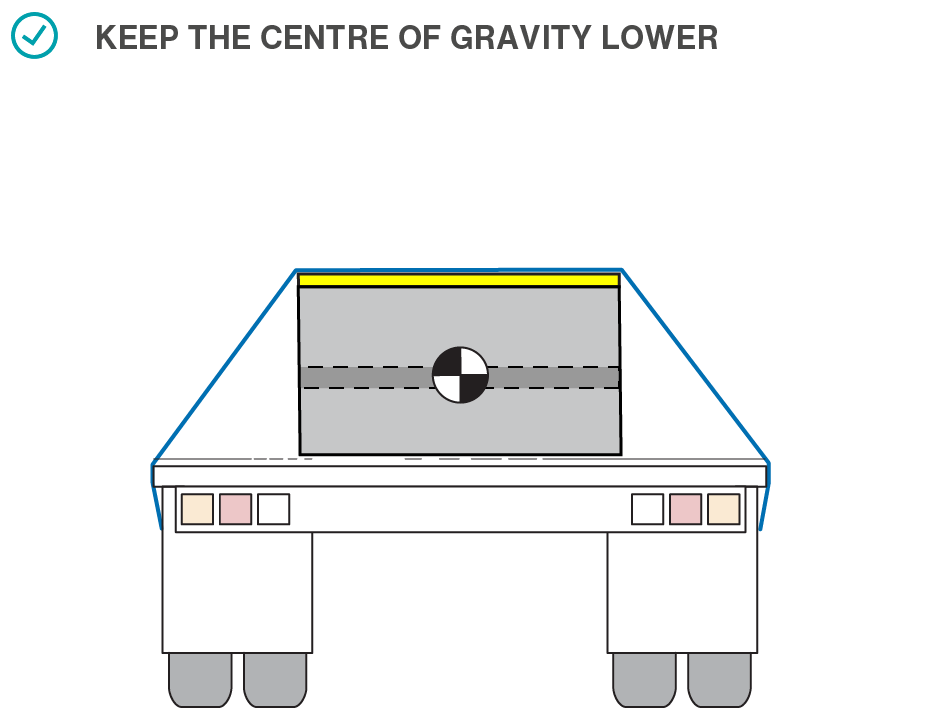

- Centre of gravity - The higher the load’s centre of gravity the more unstable it becomes.

- Vehicle movement and forces caused by - Braking, acceleration, corners, and uneven road surfaces can all increase the risk of toppling.

- Loading/packing - Uneven weight distribution, poorly secured loads, and use of inappropriate restraint equipment or equipment with excessive wear can impact the loads stability.

How to prevent toppling

Keep loads low, long and wide

- Make sure the base width is ≥0.5 (or at least 50%) of the height to prevent tipping sideways.

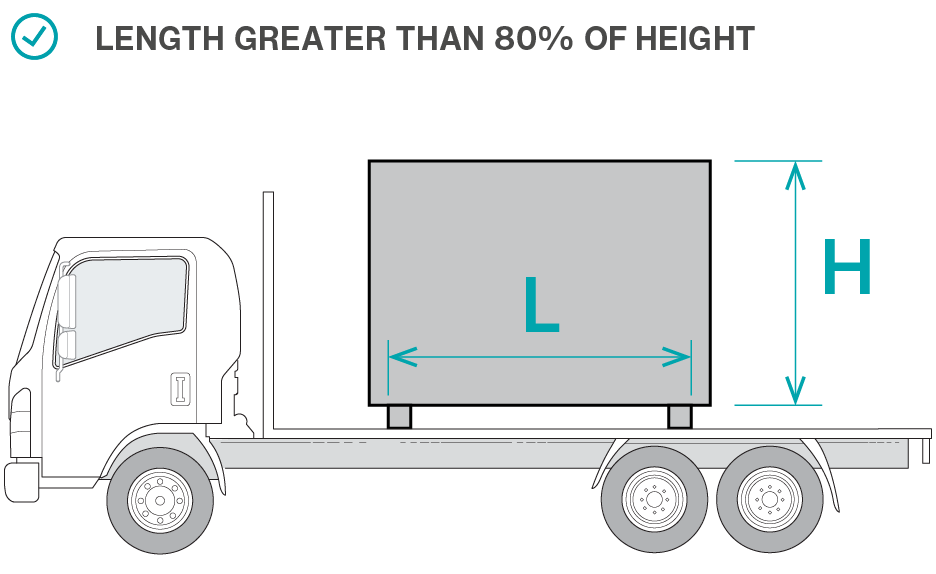

- Ensure the base length is ≥0.8 (or at least 80%) of the height to avoid tipping forward.

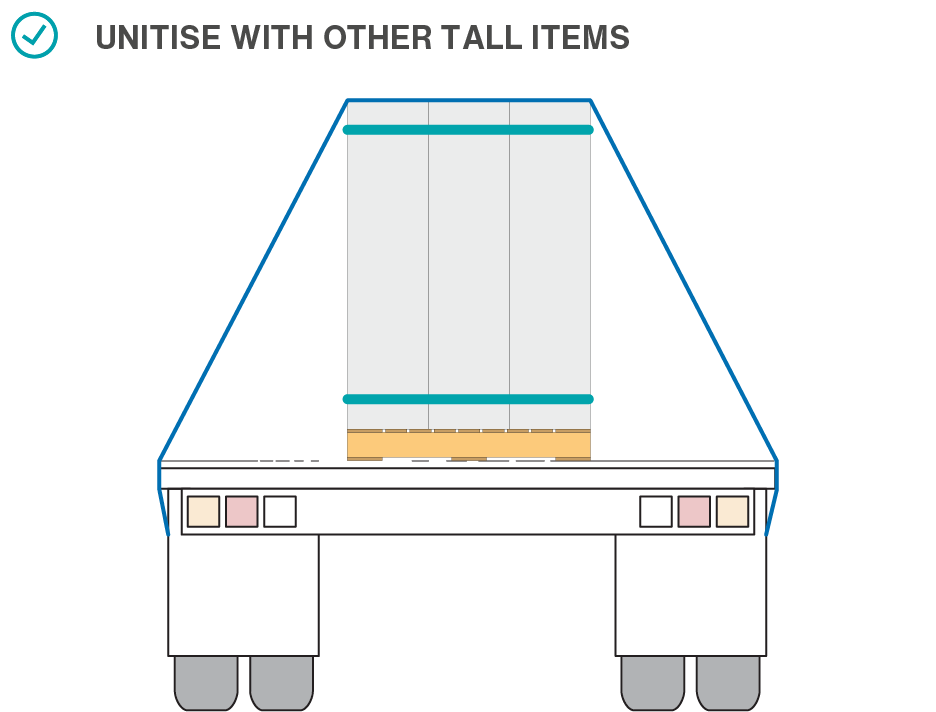

Use blocking or unitising

- Block tall, unstable items against a vehicle structure or other freight to reduce movement and prevent tipping. Find more information on this topic at Loading Guide - Blocking.

- Unitise tall items to make a more stable pack. Find more information on this topic at Loading Guide - Unitising Loads.

Consider the centre of gravity when load planning

- Stack heavier, larger items on the bottom of the load to keep the centre of gravity lower.

- Ensure the weight is evenly distributed throughout the load to maintain stability, especially during multiple pick-ups and drop-offs or when travelling over uneven road surfaces.

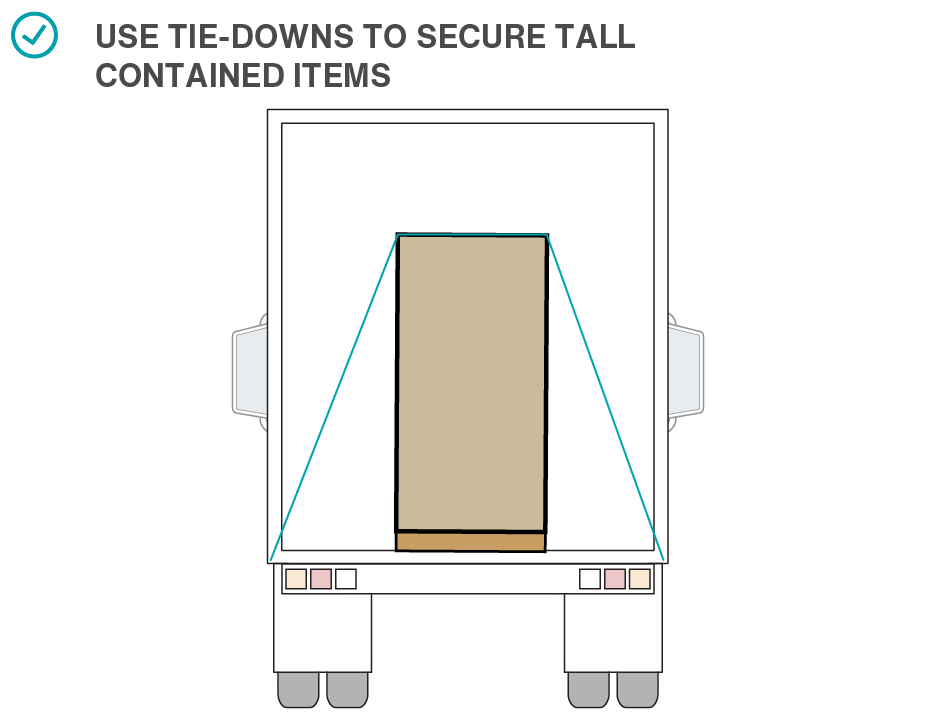

Secure the load

- Webbing straps may not be enough for tall, heavy and unstable loads. Use chains where possible as they have a limited amount of stretch.

- Fully tension your lashings and check them regularly when using tie-down restraint. Use direct lashings for extra restraint if needed.

Drive with care

- Take wider and slower turns and maintain steady acceleration and braking to minimise sudden movements that could destabilise the load.

Tips

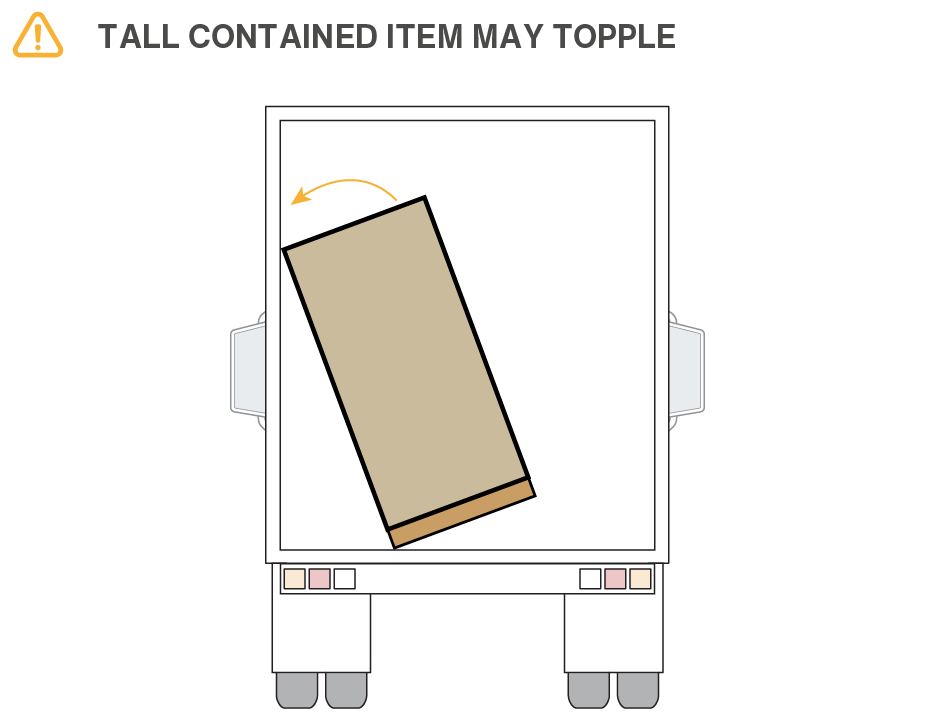

Risks

Good practice

Risks

Good practice

Risks

Good practice

Risks

Good practice

Risks

Good practice

Case study

While transporting a stack of skip bins, the load became unstable and started to tip. The height of the stack was taller than it was wide, making the load top heavy, which increased the risk of toppling.

The bins were not properly restrained to keep them from shifting. Without the appropriate support, the load became unstable, especially while the vehicle was braking and turning.

This shows how important it is to secure tall loads properly to prevent toppling. Stacking bins too high raises the centre of gravity, making them more likely to tip over. Using proper lashings, reducing the stack height or blocking the load can help make the load more secure. This makes loading, unloading and transport much safer.

Accessibility tools

Accessibility tools